Traditionally, large enterprise companies spend countless resources on bloated R&D cycles and potentially miss market opportunities when trying to iterate and bring new products to market. It doesn’t have to be this way.

Applying Lean Startup methodology to your innovation and R&D team’s workflow can get products in the hands of customers sooner and at a lower cost per iteration, thus cutting overhead and generating incremental returns that lead to increased profits.

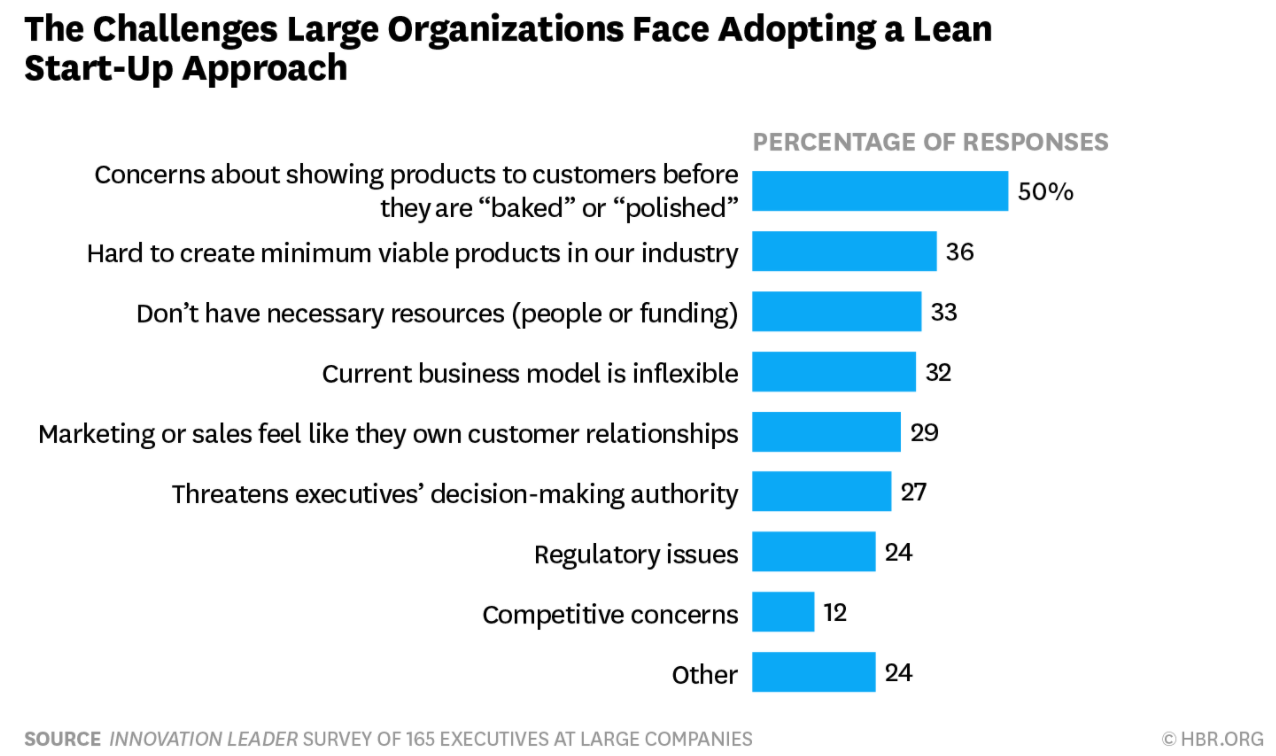

For those companies that do recognize the benefits of driving innovation with lean startup methodologies, the rapid iterations and unpolished delivery predicated by a lean startup mentality tends to make larger corporate executives uneasy. Recently, the Harvard Business Review asked executives about the opportunities and challenges to implementing agile and lean startup methods within the enterprise innovation teams and found:

The good news is, the top 3 reasons for concern are all easily resolved with the right team and resources leading your innovation efforts.

What Is The Lean Startup?

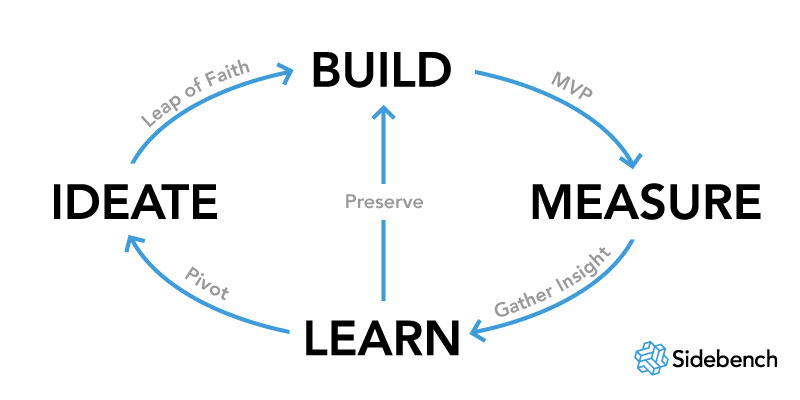

The methodology in Eric Ries’ book, The Lean Startup, has gained popularity since its release in 2011. A “Lean Startup” approach focuses on quickly creating prototypes with the goal of testing assumptions. User feedback is used to drive each iteration following an initial release allowing for much faster evolution than a traditional development process.

Like my previous article, Design Thinking isn’t just for your Product Development Team, the Lean Startup approach is typically thought of to apply to product development and rapid design prototyping of digital products. It doesn’t have to.

This is one of the most impactful concepts that has paved the way for taking an iterative approach to innovation, testing, and validating concepts. Ultimately, all are driven by a user first approach to problem solving.

Like design thinking, the Lean Startup approach surfaces a key process improvement that is essential to leading fast growing innovative companies: Build, Measure, Learn — Repeat.

But Why? Really though, Why?

A key component of The Lean Startup is asking “the five whys.” This investigative method forces people to ask simple questions to help them solve problems.

For example, take one of your current business practices. Ask why you do it (that’s one). When you come back with an answer, ask “why” again. Continue to do this until you’ve gone through the process five times.

“When this process of measuring and learning is done correctly, it will be clear that a company is either moving the drivers of the business model or not,” according to The Lean Startup. “If not, it is a sign that it is time to pivot or make a structural course correction to test a new fundamental hypothesis about the product, strategy and engine of growth.”

Ultimately asking why forces you to get to the bottom of why making this product decision is leading your product or company on a path forward. It may seem redundant, but it forces you to drill into the core of what it is you’re doing and the impact it has to your company and users.

When Lean Startup can be an Effective Driver of Innovation

Lean Startup can be used in a variety of ways. Typically you are starting a new business, but the same process can certainly be applied to larger companies undertaking a new initiative within their enterprise. Regardless of what you’re using it for, you’re on the right path if you’re asking the right questions and testing to make incremental improvements with each release.

Arguably the most attractive part of using the Lean Startup is that it minimizes risk.

The traditional route of creating a new business or product is, according to Steve Blank in the Harvard Business Review, that “you write a business plan, pitch it to investors, assemble a team, introduce a product, and start selling as hard as you can.”

However, that sets business owners and investors up with quite a bit of risk that hasn’t been validated against users.

Fortune combats an oft-cited figure that 90 percent of startups fail by citing the Boston-based investment firm Cambridge Associates that says the venture-backed startup failure rate has not risen above 60 percent since 2011. HBRsuggests that 75 percent of startups fail, and USA Today puts that number near 80 percent.

Regardless of what the actual failure rate is, the hard truth is that failure burns time and money. The lean methodology helps companies fail faster with smaller impact to minimize risk long term and create a process for incremental improvements.

Mitigating Risk is Just the Start…

Putting your customers first and iterating quickly surfaces critical data and actionable insights faster and at the forefront of every decision. Lean startup principles enforce decision making to align with tailoring your product directly to your user needs and iterate their offerings accordingly as the data suggests the need for change.

— Jay Chang, Partner & Head of Product Innovation at Sidebench

Jay is a Partner & Head of Product Innovation at Sidebench, an LA based Corporate Innovation Lab, and an advisor to the USC Blackstone Launchpad Incubator. He’s also an avid foodie, chef, & Instagrammer publishing as@BehindTheKnife on Instagram. At Sidebench, he’s worked with with enterprise companies like Red Bull, Pabst Blue Ribbon, Sony, NBC, Cedars Sinai, Oakley, Facebook, and Andreessen Horowitz. Jay graduated from the University of Southern California with a BS in Business Entrepreneurship focused on technical entrepreneurship and marketing. Throughout his multidisciplinary product focused professional career, he’s developed a deep understanding of user first experiences and business case driven approach to technology consulting.